Check it out here:

www.etsy.com/shop/DaydreamBelieverPots

Daydream Believer Pottery

Wednesday, February 3, 2016

Friday, August 14, 2015

Thursday, January 8, 2015

Wednesday, June 11, 2014

How To Stretch Your Own Canvas

Making a canvas stretcher and stretching your own canvas to paint on is super easy and a lot cheaper than buying them! You can make them whatever size you want!

First, you cut down some pine studs and add a bevel edge to make a frame, then glue your frame together, and staple or nail gun the corners together. Depending on the size of the canvas, or how heavy your painting media is, you may want to add support rails across the middle of the frame.

Second, you stretch the fabric around the frame. Put the fabric on your work surface first (I use the floor lol), then lay down the frame, bevel edge down. Staple the fabric to the back of the frame, or to the inside bevel if you're feeling adventurous. There are helpful tutorial videos at the bottom of this post.

Third, smooth those corners down, and staple them.

Fourth, if there are wrinkles in the fabric, spray with warm water and let dry. If there are no wrinkles, you can skip this step.

Fifth, gesso that bad boy! Let it dry, and you're ready to paint!!

And with a little practice, they will look professionally done, like mine:

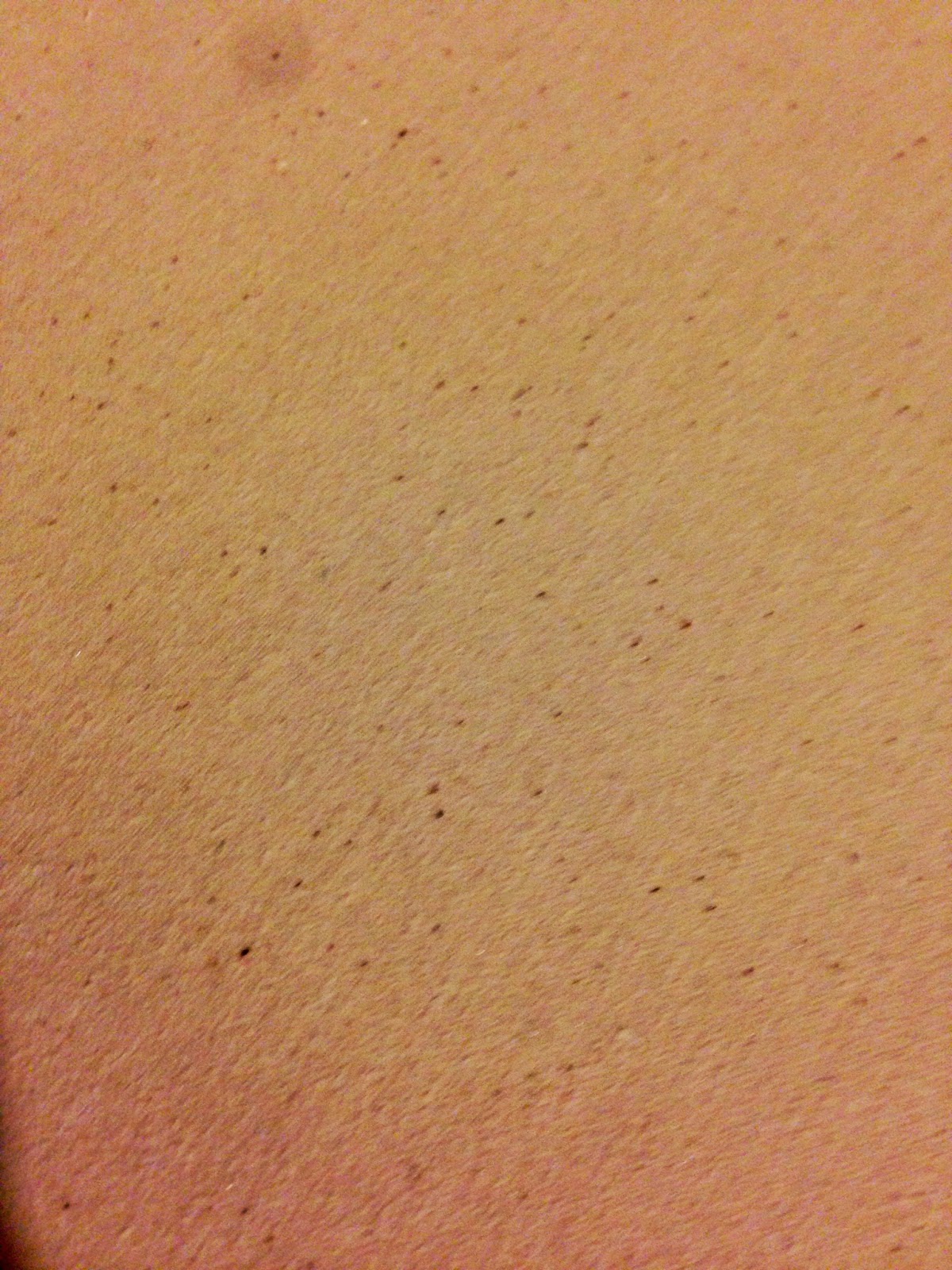

This time, I used super-thick muslin fabric instead of canvas and primed with clear gesso. Look at that natural beauty, those tiny speckles! Love it! You can use most any kind of fabric, but most people use canvas, cotton duck or burlap. And for gesso, you can use anything from cheap Kilz primer to the priciest gesso at Hobby Lobby!

Here are a couple tutorial videos on stretching canvas:

And here's one on how to get those pesky corners just right:

Sunday, December 29, 2013

Bisque Firing in my Homemade Raku Kiln

|

| It is lined with ceramic fiber insulation and ceramic buttons. |

|

| I got the trash can from Lowe's, and the fiber blanket from a store in Atlanta, GA, and the buttons from Axner. |

|

| We laid fiber blanket on cement blocks and sat the upturned trash can on top. |

|

| Then, we stacked firebricks and a kiln shelf on the fiber blanket. |

|

| The burner we used is a Venturi MR750 raku burner from Axner. I'll post pics of it and the actual firing process later. |

Sunday, June 30, 2013

Sounds Like A Dream

This place sounds amazing!

The Benini Studio and Sculpture Ranch

I wish I could put my work on display there!

Here is their blog!

The Benini Studio and Sculpture Ranch

I wish I could put my work on display there!

Here is their blog!

Sunday, June 23, 2013

Progress....

I wish I could take better photographs of my art. I am just not a photographer by any means. I respect you awesome photographers out there!

Subscribe to:

Comments (Atom)